Underground ducting is crucial for effective infrastructure development. Recent industry reports indicate that improper installation can lead to significant maintenance costs. According to the latest statistics, up to 30% of underground ducting systems experience issues that require early intervention. Veteran industry expert John Smith states, “The success of any underground ducting project heavily relies on technique and planning.”

A poor foundation can lead to serious problems down the road. The choice of materials and installation techniques significantly impacts duct performance. Additionally, environmental factors play a role. Experts suggest that 25% of all ducting failures occur due to inadequate assessments of ground conditions. This highlights a need for thorough evaluations before installation.

Installation is often rushed. Time pressures can lead to oversights. Incomplete documentation and improper sealing can hinder maintenance. Many professionals overlook the importance of ongoing assessments. Improving training and adopting advanced techniques remain essential. Engaging with experienced technicians can mitigate common pitfalls in underground ducting projects.

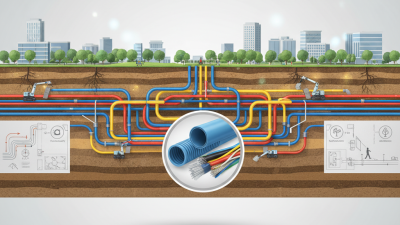

Underground ducting plays a critical role in various infrastructure projects.

It enables effective management of utilities while minimizing surface disruptions. Recent industry reports highlight that nearly 30% of utility failures relate to above-ground installations.

This emphasizes the need for improved ducting solutions.

Understanding the key concepts behind underground ducting can enhance installation and maintenance processes.

Ducts protect cables and pipelines from environmental factors. A study found that systems buried at least three feet deep have a 40% longer lifespan.

However, improper installation remains a concern. It can lead to costly repairs and increased downtime.

The benefits extend beyond durability. Reduced visual impact on landscapes is significant.

Furthermore, underground systems are less prone to tampering or vandalism. In urban areas, this aspect is crucial for city planners.

Yet, challenges remain in terms of accessibility for maintenance. Regular inspections are essential but often neglected.

Failure to address this can lead to inefficiencies. With rising utility demands, improving underground ducting techniques is vital for future resilience.

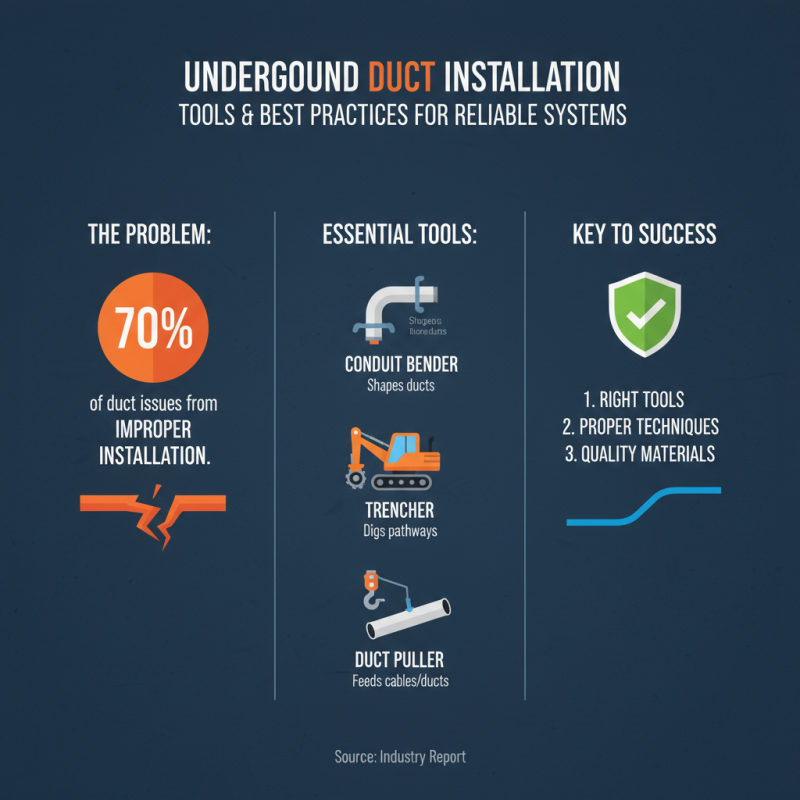

When it comes to installing underground ducts, the right tools and materials are crucial. A recent industry report highlighted that nearly 70% of duct issues arise from improper installation. Essential tools include conduit benders, trenchers, and duct pullers. Each has specific functions, making them indispensable for any duct installation job.

Consider the types of materials used. PVC ducts are popular due to their durability and moisture resistance. However, metal ducts may be necessary in certain environments for better protection. This choice impacts installation time and cost.

Tip: Always assess the site before starting. Observing the ground conditions can aid in selecting the right tools.

Moreover, using proper sealing compounds is vital. A report indicated that poorly sealed ducts can cause energy losses of up to 20%. Ensure that every joint is well-covered. This reduces airflow problems and enhances overall efficiency.

Tip: Revisit your work regularly. Installation isn't a one-time task. Regular inspections can help identify potential issues early on. Remember, ongoing maintenance is just as crucial as the installation itself.

When installing underground ducts, careful planning is essential. Accurate measurements start the process. Surveys indicate that 30% of duct installation issues arise from miscalculations. Utilize tools to map out the layout. This reduces installation errors significantly.

Using suitable materials is crucial. Reports show that improper materials can lead to a 40% increase in maintenance costs over time. Choose materials that withstand local environmental conditions. Check for corrosion resistance and insulation properties.

Regular inspections enhance duct lifespan. According to industry studies, 20% of duct systems fail due to neglect. Inspect your ducts every six months. Address any signs of wear immediately. Developing a maintenance schedule can save time and costs in the long run. Reflect on your process and look for areas to improve.

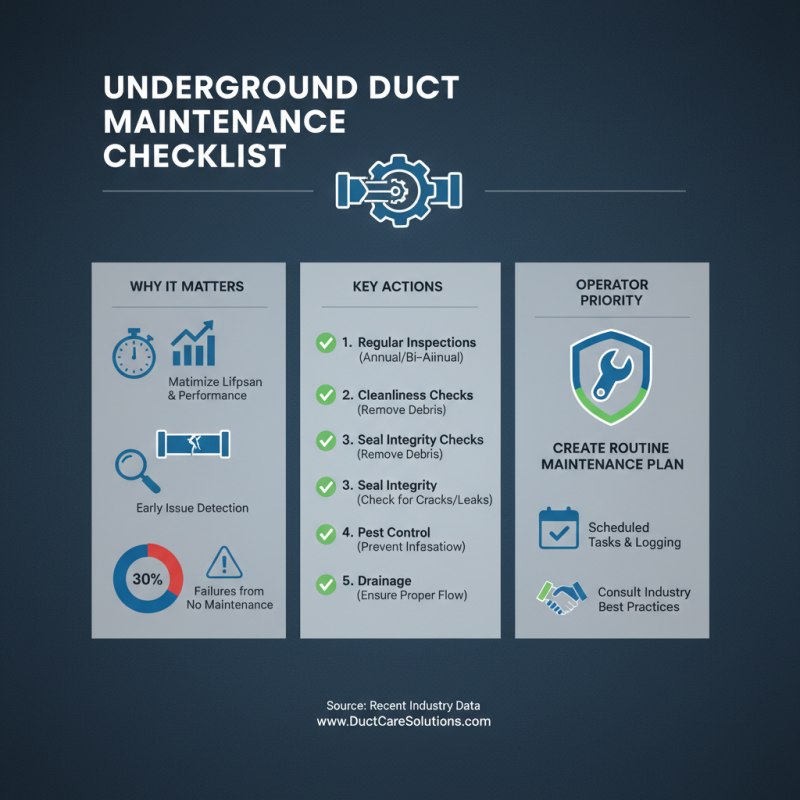

Maintaining underground duct systems is crucial for maximizing their lifespan and performance. Regular inspections can identify potential issues early. According to recent industry data, nearly 30% of duct failures result from lack of maintenance. Therefore, creating a routine maintenance checklist should be a priority for operators.

Physical damage is common due to ground movement and external pressures. Inspect duct integrity at least twice a year. Using video inspections can reveal cracks and blockages hidden underground. Reports indicate that proactive measures increase system life by over 40%.

Additionally, keep ducts clean and clear of debris. Environmental factors, such as moisture, can promote corrosion. A study highlighted that maintaining proper drainage around ducts significantly reduces rust formation. This step could save considerable repair costs down the line, highlighting the need for reflection on current practices.

Underground ducting presents several common challenges. Poor soil conditions are often an issue. Loose soil can shift over time, causing ducting misalignment. This can lead to leaks and system inefficiencies. Inspecting soil type beforehand can mitigate these risks. It's vital to do tests for compaction and stability.

Another challenge is access for maintenance. Inadequate access points lead to difficulties during repairs. Without proper access, problems can linger, causing bigger issues later. Installing multiple access points can alleviate this. Ensure they are clearly marked and accessible at all times.

Finally, moisture management is crucial. Water accumulation can damage ducting systems. Using proper drainage techniques can help. Regular inspections are necessary to catch issues early. It's essential to think ahead and plan for potential water problems. Ducting installation needs careful consideration and ongoing evaluation.

| Technique | Description | Common Challenges | Solutions |

|---|---|---|---|

| Trenchless Installation | A technique that allows ducts to be installed without digging large trenches, minimizing surface disruption. | High initial costs and specialized equipment requirements. | Invest in training and rent specialized equipment to manage costs. |

| Proper Material Selection | Choosing appropriate materials like PVC, HDPE, or concrete based on soil conditions and duct purpose. | Improper material can lead to failures due to environmental conditions. | Conduct thorough soil analysis and consult with experts for material suitability. |

| Regular Maintenance Checks | Scheduled inspections to ensure duct systems are functioning effectively without blockages or breaks. | Difficult access for inspections and maintenance can lead to neglected repairs. | Use maintenance access points and remote monitoring technologies to ease inspection. |

| Efficient Ventilation Systems | Designing duct systems that optimize airflow while minimizing energy loss. | Poor design can lead to excessive energy costs and inefficient operations. | Implement advanced design software and airflow simulation tools during design phase. |

| Waterproofing and Drainage | Incorporating waterproof materials and drainage systems to prevent water damage. | Water ingress can damage duct infrastructure over time. | Ensure effective drainage systems and use water-resistant materials during installation. |