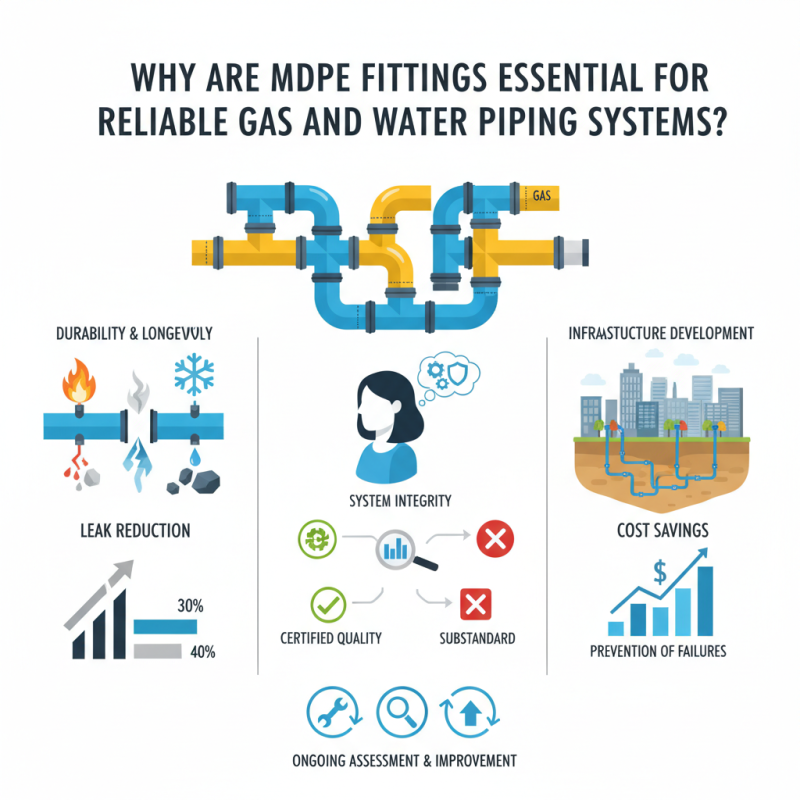

MDPE fittings play a crucial role in ensuring the reliability of gas and water piping systems. These components are designed to withstand challenging environments, offering durability and longevity. According to a recent report by the Institute of Gas Engineers and Managers, MDPE fittings reduce the risk of leaks by up to 30%. Such statistics highlight their significance in infrastructure development.

Expert in the field, Dr. Jane Smith, emphasizes, "MDPE fittings are vital for maintaining system integrity." This statement resonates with industry trends, where the demand for robust piping solutions continues to grow. Installers and engineers prioritize quality materials, seeking products that can endure harsh conditions and prevent expensive failures.

However, it's important to recognize potential shortcomings. Not all MDPE fittings are created equal. Some may lack the necessary certifications or fail to match the required standards. As the industry evolves, ongoing assessments and improvements are essential. Reliability in piping systems hinges on selecting high-quality MDPE fittings to mitigate risks effectively.

MDPE fittings, short for Medium-Density Polyethylene fittings, have gained recognition in the realms of gas and water piping systems. Their chemical resistance and flexibility make them particularly effective in challenging environments. According to industry reports by the Plastic Pipe and Fittings Association, MDPE is often chosen for its ability to withstand a range of temperatures, ensuring durability even in extreme conditions.

These fittings possess unique characteristics that enhance their functionality. They are lightweight yet strong, making installation easier and reducing labor costs. Additionally, MDPE fittings can endure pressures up to 10 bar, showcasing their reliability under various operating conditions. A report from the American Society for Testing and Materials highlights that MDPE's low thermal conductivity helps prevent condensation, reducing potential issues in water systems.

However, some challenges remain. For instance, while MDPE fittings are resistant to many chemicals, they are not impervious to all. Proper testing and calibration are essential during installation. Moreover, some users may overlook the importance of using compatible fittings and pipes, leading to potential leaks. Thus, awareness and proper education around MDPE fittings are crucial for maintaining system integrity.

MDPE fittings play a crucial role in gas and water piping systems. These fittings, made from medium-density polyethylene, offer several advantages for both residential and commercial uses. They are lightweight and durable. This material is resistant to corrosion and weather conditions, making it suitable for outdoor applications. The flexibility of MDPE allows for easy installation in various environments.

In addition, MDPE fittings can withstand high-pressure conditions. This is vital for gas transportation and water supply lines. However, proper installation is still essential. Misalignment or improper sealing can lead to leaks. Regular inspections are necessary to maintain the integrity of the system. Even the best materials can fail if not correctly managed.

Another important aspect is the compatibility of MDPE with other materials. While it connects well with certain pipes, mixing materials can create vulnerabilities. This may lead to unforeseen issues over time. It's crucial for installers to understand these nuances. They should evaluate the specific requirements of each project carefully. Understanding these factors can help ensure a long-lasting piping system.

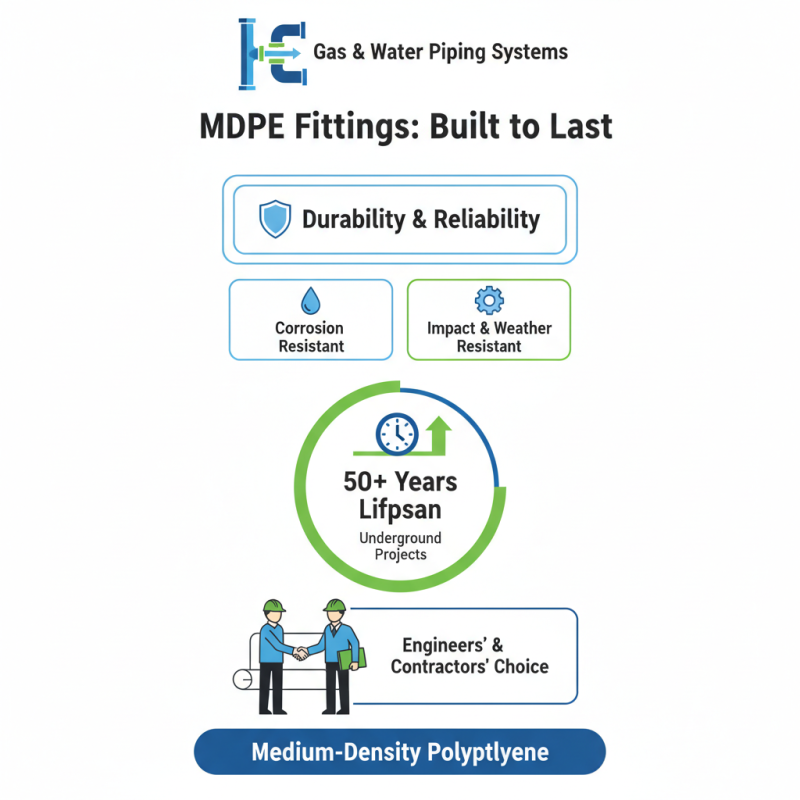

MDPE fittings are crucial for gas and water piping systems, primarily due to their outstanding durability and reliability. These fittings are made from medium-density polyethylene, which is resistant to corrosion, impact, and weathering. According to a recent industry report, MDPE pipes can last over 50 years when properly installed. This quality makes them a favorite among engineers and contractors for underground projects.

One significant benefit of MDPE fittings is their flexibility. They can adapt to ground movements without cracking. This feature is vital in areas prone to seismic activity. Moreover, MDPE fittings are lightweight, making installation easier and quicker. Data shows that using lighter materials can reduce installation time by up to 30%.

**Tip:** Always check for proper installation practices. Improperly installed fittings can lead to leaks, undermining their reliability.

Another noteworthy aspect is the reliability of MDPE in extreme temperatures. These fittings perform well in both freezing and hot conditions. Yet, it's essential to select the right fitting type for specific environmental factors. A lack of awareness about temperature impacts can lead to significant failures.

**Tip:** Regular inspections can help catch potential issues early. Scheduled maintenance is a small price for ensuring a reliable system.

When installing MDPE fittings, careful attention to detail is crucial. These fittings must be compatible with your piping materials to prevent leaks. A clear understanding of the local regulations is necessary before installation. Incorrect installation can lead to serious issues down the line.

Proper preparation is essential. The pipes should be cut cleanly to ensure a snug fit. Deburring the edges is often overlooked but key to a secure connection. It might seem tedious, yet skipping this step could result in failure.

Consider the environment as well. Underground installations must protect against soil movement. Extreme weather can affect the durability of the fittings. Each installation requires thorough planning, with adjustments made for unforeseen challenges. These proactive measures can save time and resources in the long run.

| Dimension | Description | Importance | Installation Considerations |

|---|---|---|---|

| Material Type | MDPE (Medium Density Polyethylene) | Durability and corrosion resistance for longevity in systems | Ensure compatibility with water and gas specifications |

| Joint Type | Electrofusion and Compression fittings | Secure and leak-proof connections | Proper alignment and surface preparation are critical |

| Operating Pressure | Up to 16 bar (for certain applications) | Ensures system integrity under pressure | Regular pressure testing to confirm integrity |

| Temperature Range | -40°C to 60°C | Adaptability to various environmental conditions | Avoid installation in extreme temperatures |

| Installation Tools | Wrenches, fusion machine, hand tools | Required for secure and safe installation | Use only proper tools to avoid damage |

| Standards Compliance | ISO 4427 and other relevant standards | Ensures safety and performance | Follow standardized practices during installation |

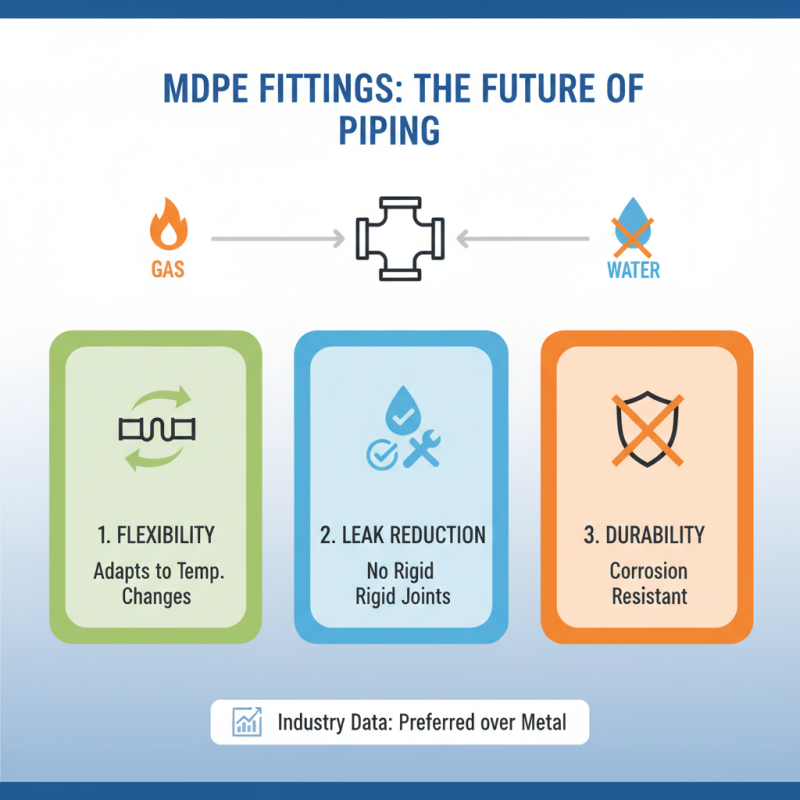

MDPE fittings are gaining momentum in gas and water piping systems. When comparing MDPE to other materials, their advantages become clear. According to industry data, MDPE has a flexibility that metal fittings lack. This flexibility allows the pipes to expand and contract with temperature changes, reducing the risk of leaks.

In contrast, PVC fittings often face issues in extreme temperatures, leading to brittle fractures. A report from the Plastics Industry Association notes that MDPE can withstand temperatures up to 60°C, while PVC typically fails beyond 40°C. This makes MDPE more suitable for various climates, enhancing reliability.

Another point to consider is the ease of installation. MDPE fittings are lightweight, which makes transport and handling simpler. Statistics show that labor costs can decrease by 15% when using MDPE due to quicker installation. However, some issues exist. Without proper fusion welding, MDPE fittings can be prone to joint failures. This necessitates careful training for installers, highlighting a need for continuous learning in the industry.