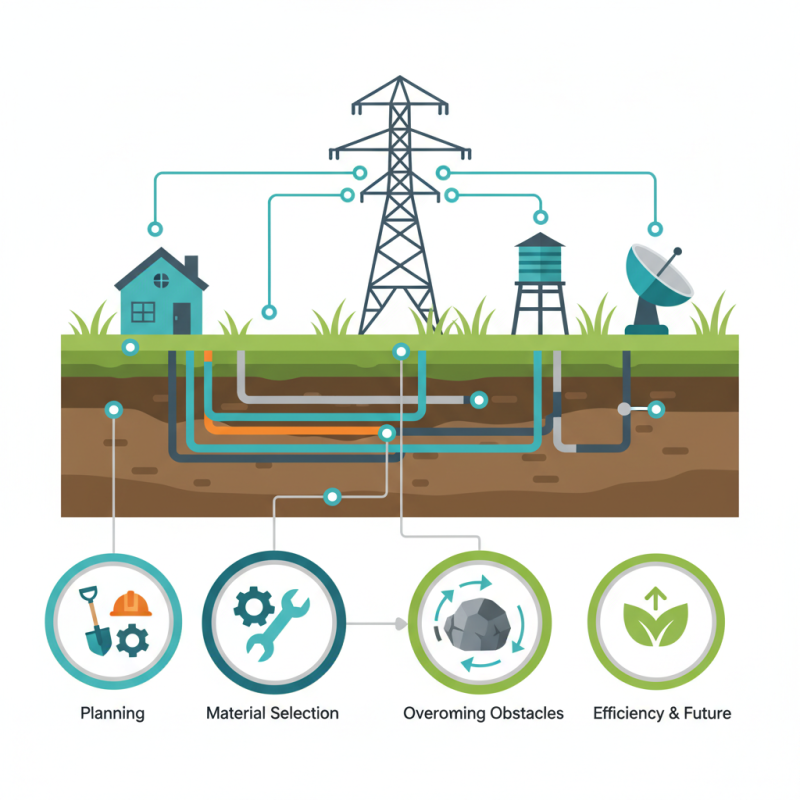

Installing underground ducting can seem daunting but is crucial for efficient utility management. This process involves laying pipes and conduits below the ground. Proper installation ensures minimal disruption to the surface and reduces energy loss.

When planning for underground ducting, consider local regulations and environmental factors. Choosing the right materials is also essential for durability. You might face challenges such as unexpected underground obstacles or changes in terrain. It's important to evaluate these factors as they can impact the installation process.

Despite the difficulties, investing time in proper installation pays off. Efficient utility management benefits everyone. However, reflection is necessary to improve planning and execution. Each project offers lessons that can lead to better results in the future.

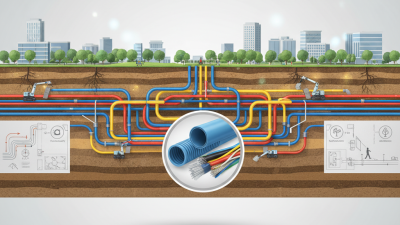

Underground ducting plays a crucial role in utility management. It safely houses cables and piping that power our homes and businesses. This infrastructure protects essential services from extreme weather. Above-ground utilities are often vulnerable to damage. For instance, a storm can easily disrupt service. Ducting mitigates this risk significantly.

Moreover, underground systems require careful planning. Installation can be complex and costly. It’s essential to consider soil types and local regulations. Improper installation can lead to issues down the line. Sometimes, even the best designs face unforeseen challenges. Maintenance is also tricky. Accessing underground utilities can pose difficulties for repairs. These factors highlight the importance of meticulous planning.

The benefits of underground ducting are clear. A well-designed system can enhance reliability. It offers long-term savings by reducing repair costs. However, it also requires ongoing attention. Regular inspections are necessary to ensure effectiveness. Balancing upfront costs with potential future savings is critical. This careful consideration directly impacts utility management success.

The following chart illustrates the efficiency benefits of proper underground ducting installation across various utility management categories. Each data point represents the percentage improvement in utility management performance due to effective underground ducting practices.

When planning underground duct installation, selecting the right materials is crucial. Not all materials are suitable for every situation. For instance, PVC can be an excellent choice for its durability and resistance to moisture. However, it may not withstand high temperatures as well as some other materials. Utility managers must evaluate the specific conditions at their installation site.

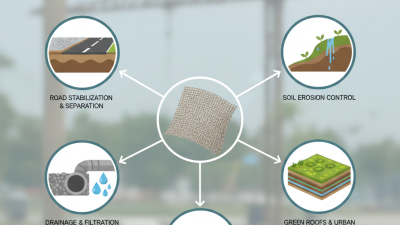

Considering soil type and local climate is essential. Sandy soils can shift, posing risks to duct integrity. Metal ducts may corrode in such environments. In contrast, HDPE is flexible and resistant to breaks, which can be beneficial in more unstable earth. These material choices often come down to cost versus performance.

It's easy to make mistakes. Often, aesthetics overshadow functionality in these decisions. Choosing the cheaper option might save money initially but can lead to costly repairs later. Regular evaluations of the chosen materials can prevent these pitfalls. Ensuring that your selected ducting can handle environmental stressors will ultimately safeguard utility management efforts in the long run.

When planning underground ducting, careful layout design is crucial. Efficient utility management relies on properly designed systems. According to a 2022 industry report, nearly 30% of utility issues stem from poor underground duct placement. Planning requires a clear understanding of site topography and soil composition. Mapping existing utilities and potential obstacles is essential.

Use CAD software to visualize your design. This helps in determining the most efficient paths for duct installation. Maintain appropriate depth and spacing to prevent liability and minimize disruption. Reports show that improper spacing can lead to costly repairs, increasing maintenance expenses by up to 20%.

Engage with local regulations before proceeding. Compliance issues can delay projects significantly. Anticipate challenges, such as fluctuating soil conditions or unexpected installations. Reflect on previous projects for improvement. Every installation is a learning opportunity. Each duct installed is a step towards better utility management, but oversight can be costly.

When installing underground ducting, attention to detail is crucial for effective utility management. Research indicates that proper installation can improve energy efficiency by up to 30%. The right techniques can decrease maintenance needs and prolong the system's lifespan.

One key installation technique is to ensure proper slope and drainage. Ducting should slope away from service points to prevent water accumulation. This is vital because water can cause insulation degradation and electrical failures. Additionally, use sturdy materials that resist corrosion and pressure.

**Tips:** Always check soil composition before digging. Compacted soil can hinder duct installation. Monitor local climate conditions, as they impact material selection. Also, consider accessibility for future repairs.

Safety should not be overlooked. Ensure trenches are properly shored up to prevent collapses. A good practice is marking existing utilities to avoid accidental damage. Always review local regulations and standards, as they vary significantly. Balancing technical precision and safety is essential for a successful installation.

Maintaining underground duct systems is crucial for their longevity and efficiency. Regular inspections can help identify issues early. According to a recent industry report, improper maintenance can decrease duct lifespan by up to 30%. A simple visual check can often reveal dirt buildup or surface damage. If neglected, these problems might lead to costly repairs later on.

Temperature fluctuation can also be a concern. Variations can cause expansion and contraction, leading to structural weaknesses. Studies indicate that maintaining a consistent temperature within duct systems can improve durability by 25%. Insulation plays a vital role here. However, installation mistakes, such as improper sealing, can undermine the insulation's effectiveness. It’s essential to address gaps proactively.

Lastly, cleaning schedules should be established based on usage patterns. Dust and debris accumulation can significantly impact airflow efficiency. Reports suggest that clogged ducts can reduce efficiency by 10 to 15%. Regular cleaning not only maintains performance but also extends the duct's functional life. Intervention after issues arise is often less effective, highlighting the need for a preventive approach.