When embarking on plumbing projects, choosing the right materials is crucial for ensuring durability and efficiency. Among the myriad options available, MDPE fittings have emerged as a preferred choice due to their versatility and resistance to various environmental factors.

According to a recent industry report by the Plastic Pipe and Fittings Association, the demand for MDPE fittings has surged, with projections indicating a growth rate of 4.5% annually through 2025. This rise can be attributed to the increasing need for reliable plumbing solutions across residential and commercial sectors, where moisture content and chemical exposure are common challenges.

Given the importance of selecting high-quality MDPE fittings, homeowners, contractors, and engineers alike must be well-informed about the different types, uses, and standards associated with these fittings to enhance the longevity and performance of plumbing systems.

MDPE fittings play a crucial role in plumbing systems, particularly in applications involving gas and water distribution. These fittings, made from medium-density polyethylene, are designed to provide a reliable connection for pipes that are often subjected to varying pressures and environmental conditions. The durability and resistance of MDPE to corrosion, chemicals, and UV exposure make it an ideal choice for both above-ground and underground installations. This resilience ensures that plumbing systems maintain their integrity over time, reducing the risk of leaks or failures that could lead to costly repairs.

MDPE fittings play a crucial role in plumbing systems, particularly in applications involving gas and water distribution. These fittings, made from medium-density polyethylene, are designed to provide a reliable connection for pipes that are often subjected to varying pressures and environmental conditions. The durability and resistance of MDPE to corrosion, chemicals, and UV exposure make it an ideal choice for both above-ground and underground installations. This resilience ensures that plumbing systems maintain their integrity over time, reducing the risk of leaks or failures that could lead to costly repairs.

Moreover, MDPE fittings are essential for ensuring compatibility with various pipe systems, offering versatility in design and installation. Their lightweight nature simplifies transportation and handling, making them suitable for both professional plumbers and DIY enthusiasts. Selecting the right MDPE fittings becomes critical as it impacts the overall efficiency and safety of the plumbing system. By understanding the importance of these fittings, individuals can make informed choices that enhance the functionality and longevity of their water and gas supply networks.

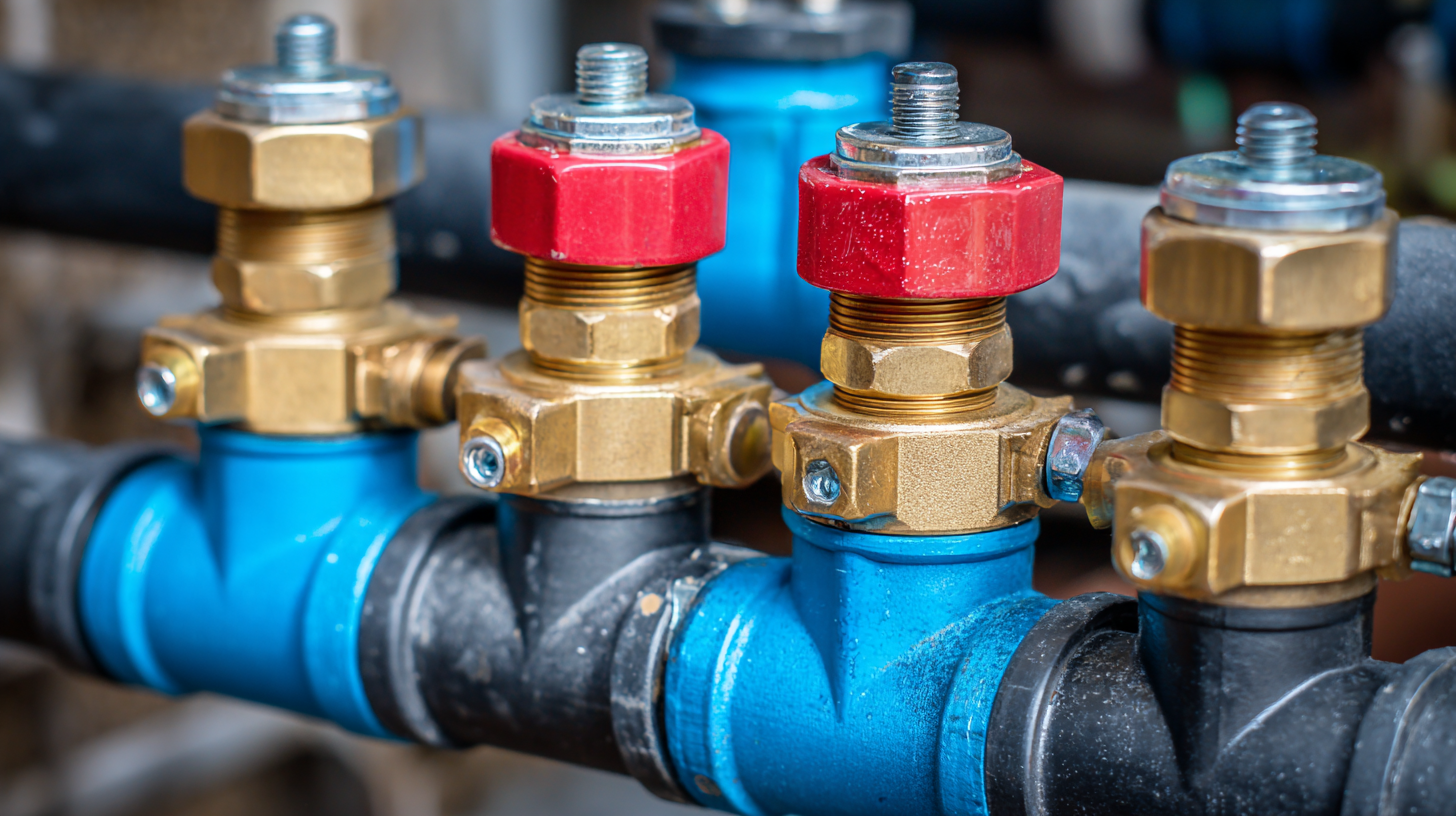

When selecting MDPE fittings for your plumbing projects, several key factors must be taken into account to ensure optimal performance and longevity. First and foremost, the compatibility of the fittings with the MDPE piping is crucial. It’s essential to check the manufacturer's specifications to ensure that the fittings can handle the pressure and temperature requirements of your specific application. Additionally, consider the intended use of the fittings; whether they are for underground installations or above ground, as different environments may require special coatings or materials to withstand corrosive elements.

Another important factor is the fitting type. MDPE fittings come in various forms, such as compression, electrofusion, or butt fusion fittings. Each type has its unique advantages and is suited for different installation methods. If transitioning between different pipe materials, choosing the correct adapters is vital to maintain a leak-free connection. Lastly, always consider the ease of installation and maintenance. Select fittings that are user-friendly and facilitate straightforward repairs or replacements, which will save time and effort in the long run.

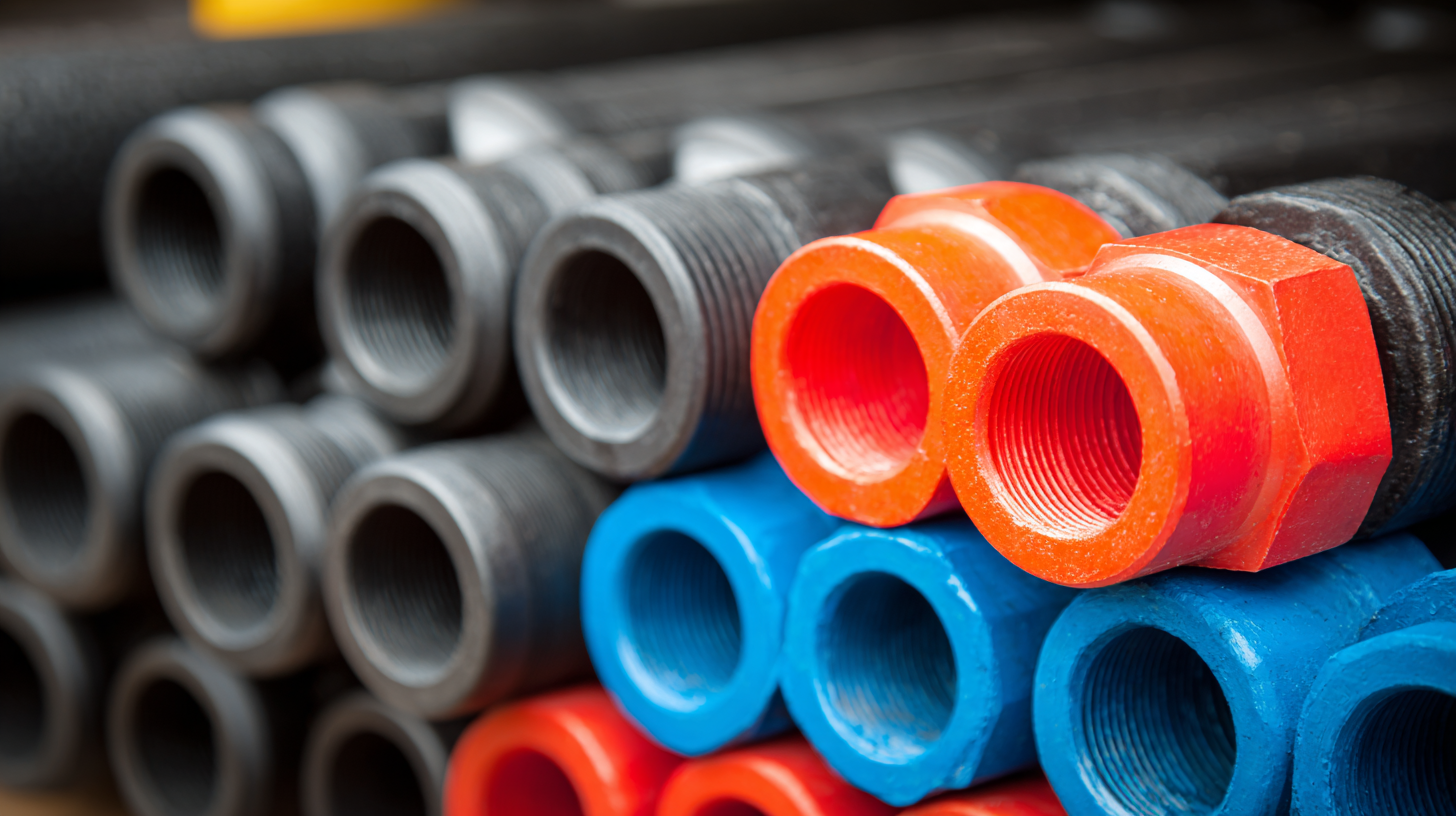

When selecting MDPE (Medium Density Polyethylene) fittings for plumbing projects, understanding the variety of types and sizes available is essential for ensuring the integrity and efficiency of your system. MDPE fittings come in various profiles including elbow fittings, tees, and reducers, each serving specific purposes in plumbing configurations. According to a report by the Global Plastic Pipe and Fittings Market, MDPE usage in water supply and irrigation systems is projected to grow at a CAGR of 5.4% from 2021 to 2028, emphasizing its importance in modern plumbing solutions. The versatility of these fittings allows seamless integration with existing systems, which is particularly beneficial in both residential and commercial applications.

When comparing different sizes of MDPE fittings, it's crucial to consider the specifications relevant to pressure ratings and flow capacities. MDPE fittings are typically available in diameters ranging from 20mm to 110mm, with pressure ratings that can vary significantly, accommodating different project requirements. The choice of size not only impacts the overall efficiency of water flow but also the durability of the system, as larger fittings may offer better resistance to burst pressure under varying temperature conditions. An analysis by the Plastics Industry Association indicates that systems utilizing appropriately sized MDPE fittings have seen a reduction in leakage rates by up to 30%, showcasing the critical role of precise sizing in maintaining plumbing system performance.

MDPE (Medium Density Polyethylene) fittings are increasingly recognized for their versatility in various plumbing applications. Commonly used in water supply systems, irrigation, and industrial piping, these fittings are engineered to withstand high pressure and temperature fluctuations. Their durability makes them suitable for both underground and above-ground installations, ensuring a reliable infrastructure for residential and commercial use.

As the global PE pipe market continues to grow, with a projected increase to $31.99 billion by 2032, the demand for high-quality MDPE fittings is expected to trend upwards. This rise can be attributed to the material's resistance to corrosion and chemicals, making it ideal for numerous applications including gas distribution and sewage systems. With the ongoing advancements in manufacturing techniques, the efficiency and longevity of MDPE fittings will only improve, further solidifying their essential role in future plumbing projects.

When it comes to ensuring the longevity of MDPE (Medium-Density Polyethylene) fittings in plumbing projects, proper maintenance is key. Regularly inspecting connections for signs of wear or leakage can prevent small issues from escalating into significant problems. It’s advisable to check fittings periodically and after any extreme weather conditions, as fluctuations in temperature can affect the integrity of the materials. Keeping the fittings clean and free from debris will also enhance their lifespan, as dirt and grime can degrade the quality over time.

Incorporating protective measures during installation is vital for durability. Avoid excessive force when tightening fittings to prevent cracking or damage. Additionally, using appropriate lubricants can ease the assembly process without compromising the fitting’s structural integrity. It’s also essential to ensure that the fittings are installed in an environment that meets their specifications; exposure to harsh chemicals or extreme UV light can lead to deterioration. By adopting these maintenance tips and being mindful during installation, you can successfully extend the life of your MDPE fittings in any plumbing project.