In the world of construction and landscaping, choosing the right materials is vital for project success. Non woven geotextile has gained popularity due to its versatile applications. These materials provide excellent drainage and soil separation. They can be used in road construction, erosion control, and even landscaping projects.

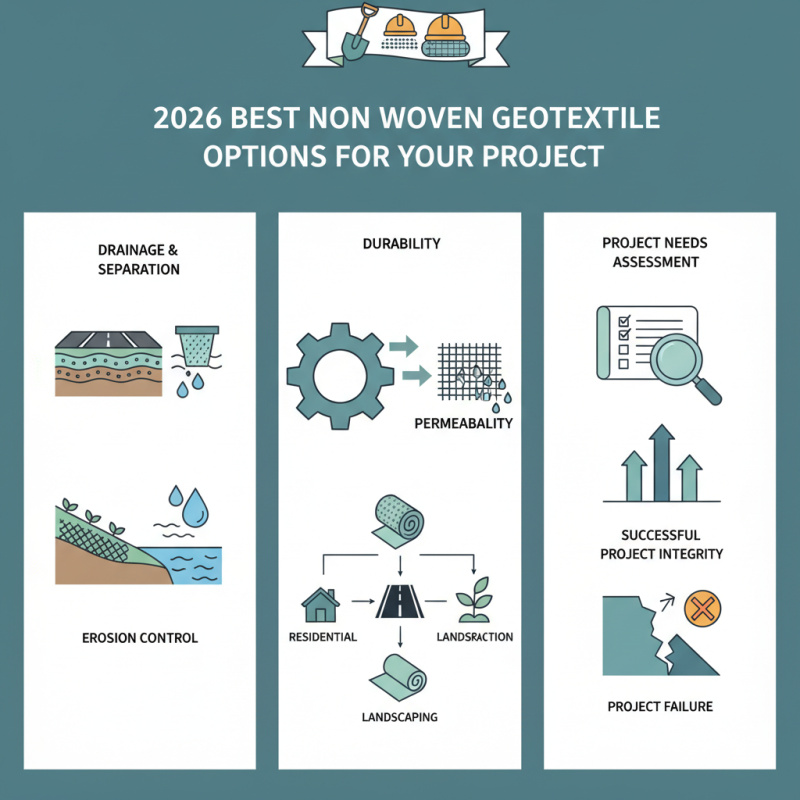

When selecting non woven geotextile, consider factors like durability and permeability. Different projects require different strengths and characteristics. Do not overlook the importance of these factors. Sometimes, arriving at the optimal choice can be challenging. It's easy to get lost in options. Thus, evaluating specific project needs helps to clarify the selection process.

It's essential to understand that not all non woven geotextiles are created equal. Some options may not perform as expected under certain conditions. Projects have unique demands, and the wrong choice can lead to failure. Reflecting on past mistakes can guide better decisions in the future. Choosing the right non woven geotextile is crucial for the integrity of your project.

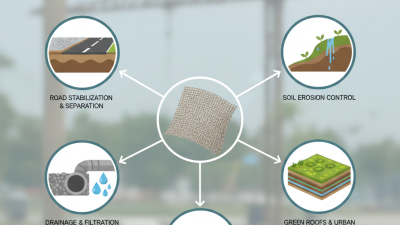

When considering non-woven geotextiles for your project in 2026, it's essential to focus on key features. Non-woven geotextiles excel in filtration, separation, and drainage applications. These materials are made from synthetic fibers, which are bonded together mechanically or thermally. The benefits are numerous. They provide excellent soil stabilization and erosion control.

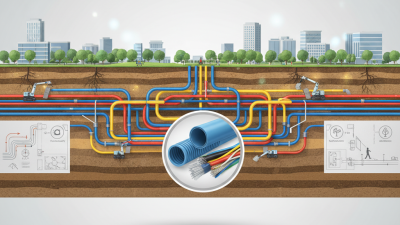

A recent industry report indicates that non-woven geotextiles can improve drainage efficiency by up to 75%. This is crucial in areas prone to heavy rainfall, where managing water flow is vital. The fabric's porosity allows for effective water passage while filtering out soil particles. In highway construction, these products can prolong the lifespan of pavement layers significantly compared to traditional methods.

Tips: Always evaluate the project's specific needs. Consider factors like soil type, load-bearing requirements, and environmental conditions. Doing this can lead to better material selection. Not all non-woven geotextiles are created equal; some may not perform as expected in challenging conditions. Regular testing and field evaluations can help pinpoint the right choice for your project. Remember that investing in quality materials can save costs in the long term.

Non woven geotextiles are versatile materials used in many construction and landscape projects. They are made from synthetic fibers that are bonded together using heat, chemicals, or needle punching. This creates a fabric that has unique properties suitable for various applications.

One common type is the staple fiber geotextile. It is ideal for filter applications. Its large surface area helps retain soil while allowing water to pass through. This type can often be used in drainage systems. Another option is the continuous filament geotextile, which offers superior strength and durability. It is suitable for reinforcing soil. Projects like roads and retaining walls benefit greatly from this material.

Choosing the right type involves careful consideration of your project's requirements. Factors like soil type and moisture levels matter. Not every project may require a high-end option. In some cases, a more basic type might suffice. This reflects the need for practicality over trendiness. Balancing cost and functionality is essential for effective project management.

When selecting non-woven geotextiles for your project, several key factors deserve attention. First, consider the material composition. Non-woven geotextiles often contain polypropylene or polyester. These materials offer great strength and flexibility. According to industry reports, polypropylene geotextiles have a high tensile strength, which makes them suitable for various applications.

Another important factor is the permeability of the fabric. A non-woven geotextile should allow for adequate water flow while preventing soil erosion. Studies show that the permeability rate can significantly impact drainage efficiency. Choosing the right permeability ensures your project’s longevity. Additionally, evaluate the durability of these geotextiles. They should withstand environmental challenges, such as UV exposure and chemical pollutants.

Lastly, installation ease is often overlooked. Some types of geotextiles can be cumbersome to work with. This might lead to delays and increased labor costs. Opting for a material that is easier to handle can improve overall project efficiency. Make informed choices based on detailed project requirements and environmental conditions.

When exploring the non woven geotextile market in 2026, understanding top brands and products is critical. Recent industry reports indicate that the global geotextiles market is expected to grow significantly, with non woven geotextiles representing a substantial segment. These materials are known for their effective filtration and drainage properties, often used in drainage systems and erosion control.

Some of the prominent choices on the market include various fabric weights and compositions. For instance, industry statistics indicate that non woven geotextiles in the range of 100 to 150 GSM are popular for applications where soil stabilization is essential. However, our analysis shows some gaps in performance standards among different manufacturers, which can lead to unexpected project failures if not carefully evaluated.

The longevity and durability of these products are critical factors. While many manufacturers claim high resistance to UV degradation, practical evidence suggests variability. Some non woven geotextiles may fail sooner than expected, especially under harsh conditions. It's essential to analyze not just marketing claims but actual performance data. Selecting a geotextile should involve a thorough review of independent test results and customer feedback to mitigate potential risks.

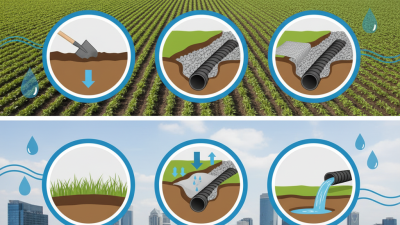

When installing non-woven geotextiles, proper preparation is key. Begin by clearing the area of any debris. This ensures a clean surface for the geotextile to lay flat. If the ground is uneven, consider grading it to prevent wrinkles. Every wrinkle or fold can affect the material’s performance. Pay close attention to the edges during placement; they need to overlap correctly to avoid gaps.

While laying down the geotextile, use sandbags or stakes to hold it in position. Wind can easily disrupt loose materials, leading to misalignment. An effective installation requires patience; rushing can lead to mistakes. Ensure the fabric remains taut without excessive stretching. This balance influences both water flow and soil separation. Remember to regularly check your alignment as you work. Small adjustments can prevent larger issues later on.

In some cases, you might find unexpected challenges like rocky terrain or heavy rainfall. These can complicate installation and affect geotextile functionality. Rather than overlooking these hurdles, take time to adjust your methods. This reflection can improve future projects. Consider consulting guides or professionals when in doubt about complex conditions.