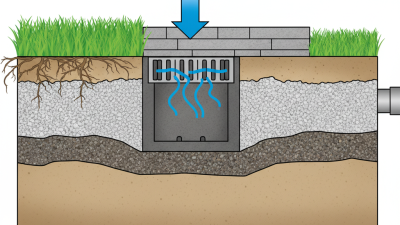

When it comes to drainage systems, the role of an inspection chamber cannot be overstated. A recent industry report noted that nearly 40% of drainage issues stem from inadequate access to inspection points. Inspection chambers provide crucial access for maintenance and inspection of drains, ensuring they function correctly. These structures allow for the identification of blockages and other problems, which can save homeowners significant costs in repairs.

Choosing the right inspection chamber requires careful consideration. There are various designs and materials available, and each has distinct advantages. For instance, chambers made from polymer offer durability and resistance to corrosion. However, some homeowners may overlook the importance of size and accessibility. According to market insights, 30% of properties do not have adequate inspection points, leading to potential drainage failures.

Investing in the best inspection chamber option is essential for long-term drainage health. You should weigh factors like installation requirements and environmental impact. The choices might feel overwhelming, but selecting the right one will enhance your drainage system's effectiveness. A poorly chosen inspection chamber can lead to inadequate maintenance access and increased costs down the line. Reflecting on these details will ensure a more reliable drainage solution.

Inspection chambers play a crucial role in drainage systems. They provide access points for maintenance and inspection of pipes. Regular checking can prevent blockages and costly repairs. Properly functioning chambers help ensure efficient water flow. Without them, homeowners might face significant issues during heavy rains.

When selecting an inspection chamber, consider various factors. The material and size are essential. You want something durable but also easy to access. A poorly chosen chamber can complicate repairs. It can also lead to increased costs later. It's tempting to cut corners, but this often leads to regrets.

Understanding the importance of these chambers means recognizing their maintenance needs. Regular inspections are necessary. Ignoring them may result in bigger problems down the line. Homeowners must be proactive in their drainage choices. Reflecting on past experiences can guide future decisions. Every choice matters when it comes to drainage systems.

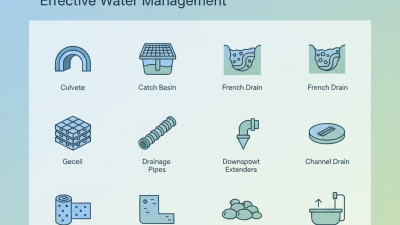

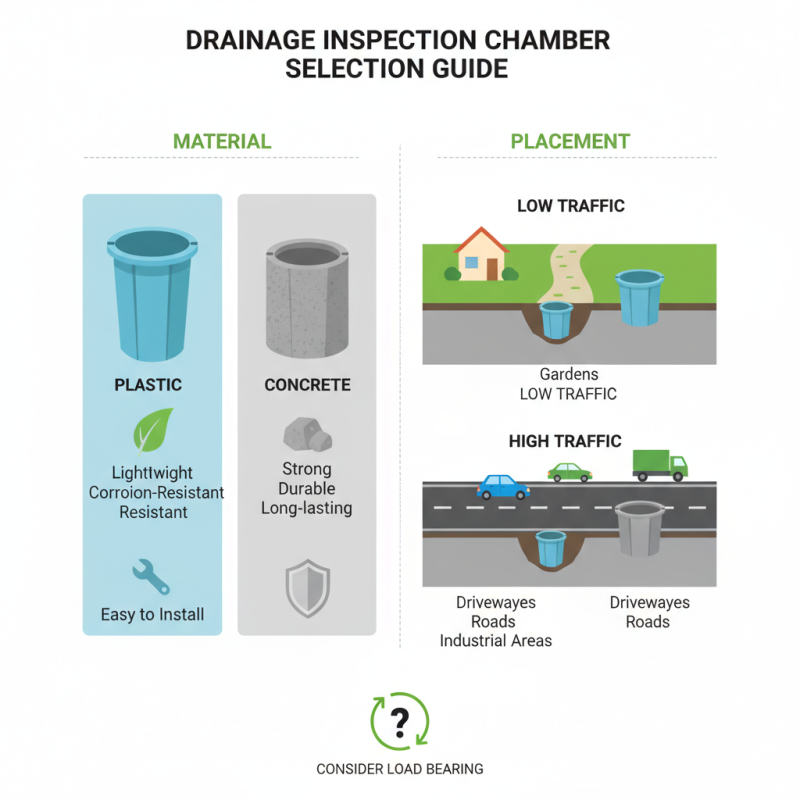

When selecting an inspection chamber for drainage systems, several key features are vital. The material of the chamber plays a crucial role. Options like plastic and concrete offer different durability. Plastic is lightweight and resistant to corrosion. On the other hand, concrete provides strength and longevity. Think about where the chamber will be placed too. Will it be in a high-traffic area? This factor can influence material choice.

Another important aspect is size. Inspection chambers come in various dimensions. A larger chamber may simplify access for maintenance. However, oversizing can increase costs unnecessarily. Standard sizes often meet most needs, but always measure carefully. Depth is equally significant. Ensure that the chamber can accommodate your drainage layout without issues.

Finally, consider installation ease. Some models are easier to install than others. Complexity can lead to higher installation costs. Check user reviews on assembly experiences. Additionally, inspect the design. A well-designed chamber will facilitate easy access for cleaning and inspections. Finding a balance in all these features can lead to the best choice.

When it comes to drainage systems, choosing the right inspection chamber is crucial. These chambers allow easy access to your drainage pipes, aiding in maintenance and repairs. A good inspection chamber should be durable, able to withstand harsh conditions and heavy loads. Many designs offer reinforced materials for added strength, but flaws can still exist. Sometimes the seals wear out, leading to leaks. Checking for such issues periodically is essential.

Functionality often varies among different models. Some chambers come with pre-installed lifting handles or removable covers. This can make access much easier during inspections. However, not all features are practical. For example, some designs might not align well with existing drainage systems, causing installation headaches. It can be frustrating to find that the perfect chamber does not fit as expected. Balancing durability and functionality requires careful consideration.

Selecting the right inspection chamber involves more than just checking the specs. Real-world testing is often needed to ensure they perform as advertised. You may also need to account for environmental conditions in your area. It’s wise to gather feedback from others who have used various models. This might prevent costly mistakes in the future. Inspecting these chambers regularly can then help maintain your drainage system's longevity.

| Model | Material | Depth (mm) | Load Rating (kN) | Price ($) |

|---|---|---|---|---|

| Model A | Polyethylene | 600 | 12 | 150 |

| Model B | Concrete | 750 | 15 | 200 |

| Model C | Fiberglass | 500 | 10 | 120 |

| Model D | PVC | 400 | 8 | 100 |

| Model E | Metal | 650 | 20 | 250 |

| Model F | Composite | 550 | 18 | 180 |

| Model G | Steel | 700 | 25 | 300 |

| Model H | Reinforced Concrete | 800 | 30 | 350 |

| Model I | HDPE | 650 | 15 | 220 |

| Model J | Aluminium | 400 | 10 | 90 |

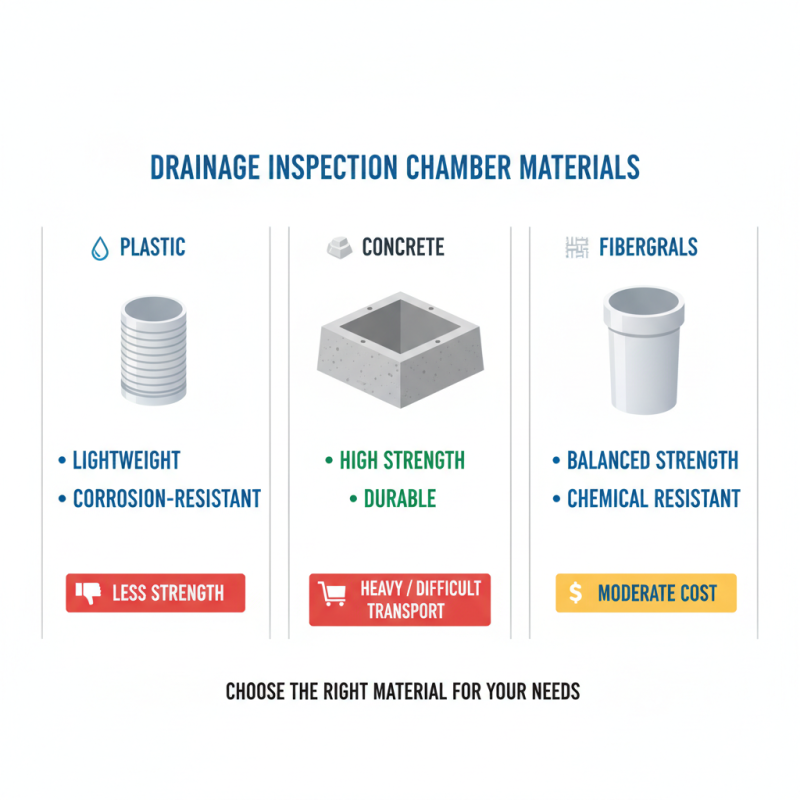

When choosing an inspection chamber for drainage needs, material plays a vital role. Common materials include plastic, concrete, and fiberglass. Each has its benefits and drawbacks. Plastic chambers are lightweight and resistant to corrosion. They can withstand harsh chemicals present in wastewater. However, they may lack the strength of concrete options.

Concrete inspection chambers offer durability and load-bearing capacity. They are often preferred in heavy-duty applications. According to industry data, 70% of infrastructural projects still favor concrete for its longevity. On the downside, concrete can crack under extreme temperature variations and is prone to structural failures if not installed correctly.

Tip: Always consider environmental factors before selecting materials. Moisture levels and chemical exposure influence durability. Fiberglass is another option. It combines lightweight benefits with resistance to corrosion. However, it can be more expensive. Weigh the pros and cons carefully. Your choice could impact maintenance frequency and long-term costs. Remember, it’s not just about immediate needs but also future demands.

When installing an inspection chamber, proper placement is key. Industry studies indicate that almost 80% of drainage issues stem from improper installation. A well-placed inspection chamber facilitates easy access for maintenance. It should be located in areas with minimal foot traffic. Consider soil type and potential groundwater levels when selecting the site.

Maintenance is critical for longevity. Regular inspections are necessary to catch blockages early. A report from the Drainage Association shows that neglecting maintenance can double repair costs over time. Check for debris accumulation or signs of damage at least twice a year. Seasonal changes impact drainage systems. Be proactive, especially before heavy rainfall.

Choosing the right material for the inspection chamber matters. Each type offers different durability ratings. Studies reveal that materials like PVC and concrete can last over 30 years with proper care. However, wear and tear can lead to unexpected failures. Assessing wear regularly helps avoid costly repairs. Adjusting your maintenance routine based on usage can improve overall system performance.