The 63mm MDPE pipe is a versatile option in plumbing. It is made from medium-density polyethylene, offering durability and resistance to corrosion. This pipe is useful for various applications, such as water supply and drainage systems.

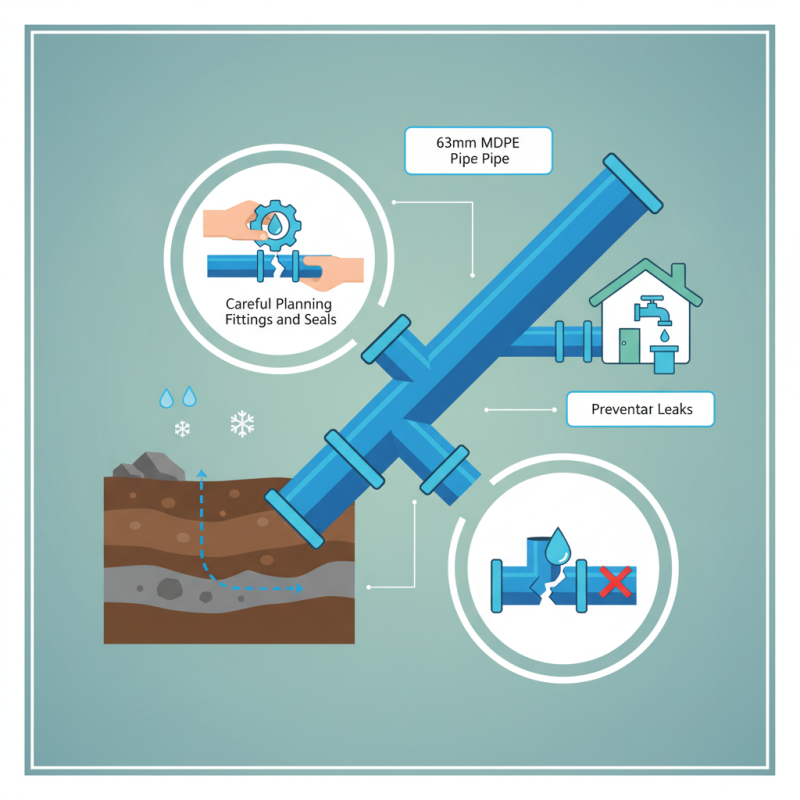

The robust nature of the 63mm MDPE pipe makes it suitable for underground installations. It can handle extreme weather conditions, making it a reliable choice. However, installation requires careful planning to avoid potential challenges.

Often, users overlook some essential factors. Proper fittings and seals are key to prevent leaks. While the pipe is strong, improper handling can lead to damage. Reflecting on such details can enhance its effectiveness in plumbing systems.

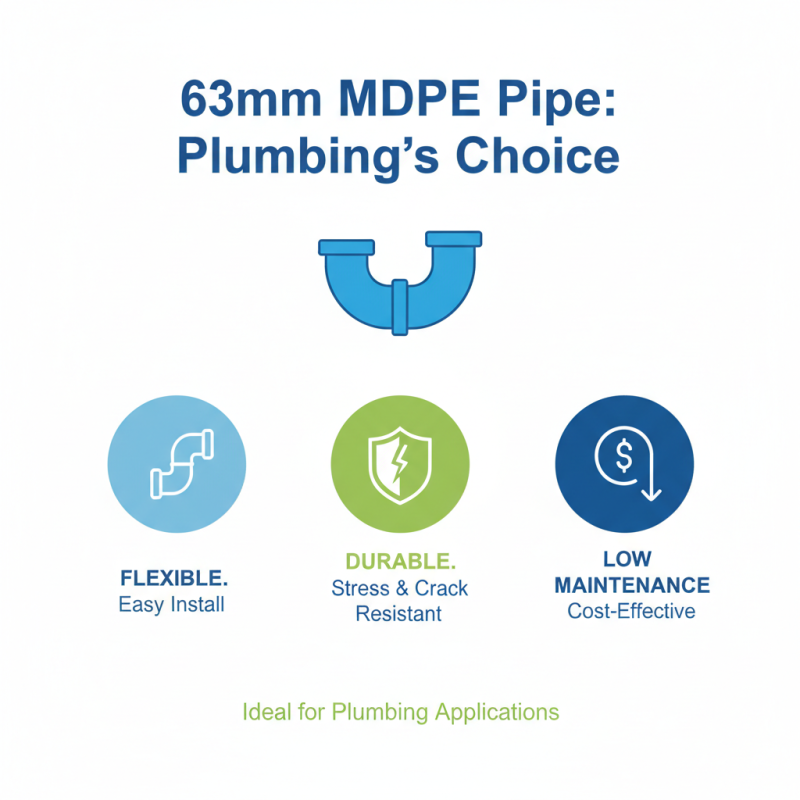

63mm MDPE pipe, made from medium-density polyethylene, has unique characteristics that make it ideal for plumbing applications. Its flexibility allows for easy installation, even in challenging environments. According to industry data, it has a high resistance to stress and cracking, which enhances durability. This means lower maintenance costs for plumbing systems.

The pipe also boasts excellent chemical resistance. It can withstand substances like acids and bases without degrading. Many engineers prefer MDPE for water supply systems due to its low permeability to gases. This feature helps maintain water quality. However, some may find that MDPE can become brittle in extremely cold temperatures, raising concerns about its long-term performance in such climates.

In terms of diameter, the 63mm size is optimal for household plumbing. It allows substantial water flow. Data indicates that using the right diameter reduces pressure loss significantly. However, improper installation can lead to leaks and wastage. Thus, attention to detail during installation is critical. Some installers may overlook proper jointing techniques, which could undermine the system's longevity.

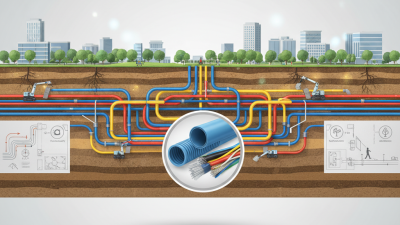

63mm MDPE pipe, or medium-density polyethylene pipe, is widely used in plumbing, especially for water supply systems. Its structure makes it lightweight yet durable. This flexibility allows for easy installation in various settings. The 63mm diameter is suitable for both residential and commercial applications. It handles high pressures and adapts well to different terrains.

In water supply systems, 63mm MDPE pipe is common for service connections. It is often used to link the main pipeline to households. The smooth interior of the pipe minimizes friction, resulting in efficient water flow. This kind of pipe is resistant to corrosion, ensuring longevity. Users appreciate not having to worry about rust or scale buildup.

However, installation challenges arise sometimes. Ground movement can cause stress on the joints. Also, improper handling during installation can lead to leaks. These issues require careful planning and attention to detail. Thoughtful consideration of local conditions can help mitigate some risks. Overall, 63mm MDPE pipe remains a valuable choice in plumbing for its reliability and practicality.

63mm MDPE pipe is a reliable choice for plumbing projects. It stands out due to its durability and resistance to corrosion. This type of pipe is designed to handle both water and gas. Its flexibility also allows for easy installation in various environments.

One advantage of using 63mm MDPE pipe is its ability to withstand high pressure. This feature is essential in preventing leaks. Additionally, MDPE pipes are lightweight, which simplifies transportation and handling. They are also less likely to break, reducing maintenance costs.

Tips: Ensure proper insulation when installing MDPE pipes outdoors. This can prevent issues during winter months. Also, always check local regulations regarding pipe specifications. This will keep your project compliant. Finally, consider potential expansions or changes in your plumbing needs. 63mm MDPE pipes can accommodate future modifications well, but planning ahead is crucial.

When discussing 63mm MDPE pipe, it's essential to understand the industry standards and specifications governing its use. This type of pipe typically complies with standards such as ISO 4427, which outlines requirements for polyethylene pipes used in water supply systems. It is also essential to adhere to local regulations and guidelines for plumbing installations, ensuring safety and reliability.

The material properties of MDPE make it suitable for various applications. Its robustness allows it to endure pressure and temperature fluctuations. However, improper installation can lead to issues such as leaks or bursts. Careful attention to details during installation is crucial. Pipe fittings and connectors must also meet relevant standards to ensure compatibility.

One common misstep is overlooking the importance of correct burial depth. This can impact the pipe's durability and performance. In colder climates, deeper installations might be necessary to prevent freezing. Regular maintenance checks can further ensure the integrity of the piping system. Awareness of these standards can enhance the overall effectiveness of using 63mm MDPE pipe in plumbing systems.

| Specification | Details |

|---|---|

| Material | Medium Density Polyethylene (MDPE) |

| Outer Diameter | 63 mm |

| Wall Thickness | Variable (commonly 4.5 mm to 5.0 mm) |

| Pressure Rating | Typically 12.5 bar to 16 bar |

| Applications | Water supply, gas distribution, irrigation systems |

| Temperature Range | -20°C to +40°C |

| Standards | ISO 4427, BS 6572 |

| Jointing Methods | Electrofusion, butt fusion, compression fittings |

63mm MDPE pipe is a popular choice in plumbing projects. It’s often compared to other pipe materials like PVC and copper. This analysis focuses on key differences and ideal uses.

MDPE stands for medium-density polyethylene. This material is flexible and resistant to various chemicals. It can handle high pressure, making it suitable for water supply. In contrast, PVC is rigid but lightweight. It’s more affordable but not as durable under continuous stress. Copper pipes are durable and resistant to corrosion, but they are heavier and expensive.

When considering installation, MDPE pipes are easier to work with. They can be installed quickly due to their light weight. However, they may require special fittings for some configurations. This is a common area where installers can face challenges. The choice between these materials can depend on factors like budget, application, and local regulations. Each material comes with its pros and cons, which may lead to critical reflections on project needs.